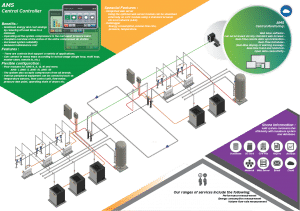

AMS

Central Controller

Benefits :

– Maximum energy and cost savings by reducing off-load times to a minimum

– Operating all the system compressors to the narrowest pressure band

– Complete overview of the status of the entire compressed air station

– Increased system reliability

– Reduced maintenance cost

Features :

– There are controls that support a variety of applications (Rotary or Sequence Control, Turn-back, etc.)

– Can connect in many ways according to actual usage (single loop, multi loop, master-slave, remote i/o, etc.)

Flexible configuration :

– Four modules for AMS-4, 8, 12, 16 and more.

AMS- I, AMS- II, AMS- III, AMS- IIII

– The system also accepts compressors from all brands.

– Various peripheral equipment can be connected such as temperature sensors, flow control unit, flow meter, pressure dew point, operating state of dryers,auto drain, waste water treatment, control valve etc.

Special Features :

– Integrated web server Using the optional web server module can be visualised externally on a PC module using a standard browser via local network (LAN).

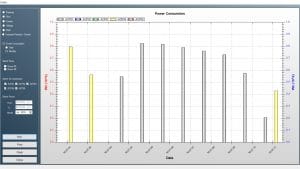

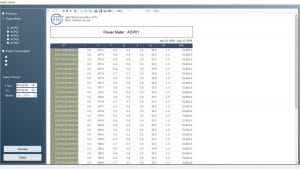

– Datalogger

Energy consumption,volume flow rate, pressure, temperature.

Share Information :

AMS series communicates effivienty with business system and databases.

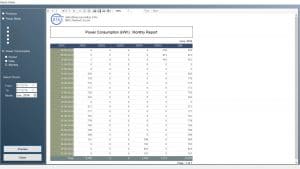

- Database (SQL Server, MySql, Postgressql, etc..)

- Report (Excel, Pdf)

- Export CSV file

- SD memory card : SD and SDHC

- MODBUS Ethernet

- MODBUS RTU

- OPC

- Web Server

- SMS or Email

Technical Data :

- Wide screen format

- Wide operating temperature -10°C to +60°C

- Powerful ARM Cortex-A9 processor

Powerful dual or quad core ARM Cortex-A9 processor delivers fast screen changes and program execution in demanding application. - SD memory card

- USB Port : 1 x USB 2.0

- Ethernet port

AMS

Central Monitoring :

- 100% pure web base software

- Can be accessed via any standard web browser w/o single download/plugin

- Responsive HMI

- Minimum system requirements compared to others

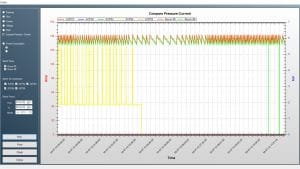

- Real-Time remote data synchronization

- Real-Time Database

- Real-time display of warning message

- Real-time trend and historical

- Open data connectivity

- HTTPS secure web connection

- SSL encryption

- Data protection

- Internet Gateway connects your SCADA on cloud

- Emerging to IIoT world

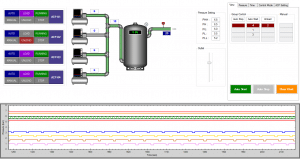

Sequence Control Simulation :

|

|

|

|

|